Power Generation

Solutions for the Power Generation industry

Outstanding quality and exceptional performance

Experience that drives innovation

For over 70 years, Conax has designed and manufactured compression seal fittings, temperature sensors and cable and harness assemblies for a broad range of applications across the Power Generation industry. Our innovative designs help reduce costs to OEM and lower maintenance times for end users.

We listen to our clients and work with them as partners to engineer customized solutions for every challenge they face. Our comprehensive solutions have been applied to:

- Heat recovery steam generators (HRSGs)

- Internal combustion engines and turbochargers

- Steam and wind turbines

- Waste energy cogeneration

- Hydroelectric, nuclear and solar power

- Fuel cells

Download our brochure for the Power Generation industry.

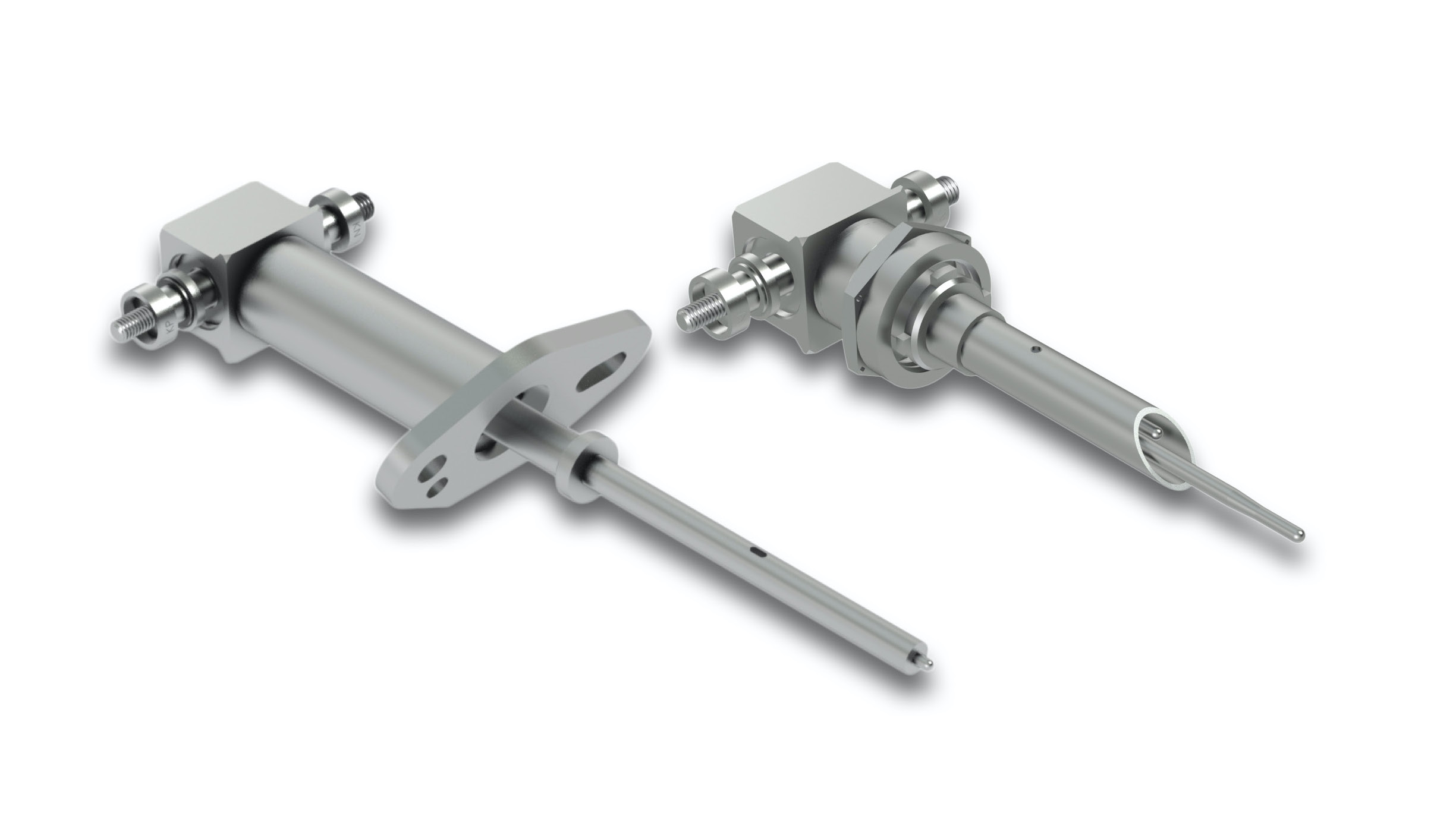

Competitively-priced exhaust gas sensors for LM Series engines

With a proven history of manufacturing reliable temperature sensors for large frame gas turbines and aeroderivative engines, Conax Technologies now offers an aftermarket equivalent for LM engines that offers significant cost savings.

Conax exhaust gas sensors for LM6000 T4.8 and LM2500/LM5000 turbines are engineered from state-of-the-art materials that are fully interchangeable with OEM products and offer excellent mechanical strength and superior oxidation creep resistance.

The Conax sensors are available at a competitive price point, are interchangeable on all LM ground-based applications, and are in stock for fast delivery. For more details, click here.

Customized EGTs for FT8 aeroderivative ground-based turbines

Pratt & Whitney FT8/GG8 frame users are choosing Conax Technologies’ exhaust gas thermocouples (EGTs) over OEM sensors in their turbines. Conax Technologies’ superior design meets or exceeds OEM functionality and has proven to be highly reliable through field testing and validation.

Conax uses two dual circuit ungrounded thermocouple probes that are manufactured for balanced loop resistance among all four circuits. This is superior in design to the OEM version that utilizes four single thermocouple probes.

Plus, our solution uses a four-post hermetic connector that exceeds OEM specifications and is adaptable to the existing cable harness. For more details, click here.

A commitment to quality

Conax works with industry leaders to create high-quality, custom-designed temperature sensors and cable and harness assemblies for a wide variety of critical components, and our Quality Management System is dual certified to AS9100D with ISO 9001:2015. Conax is fully capable of producing sensors that are accurate, robust and repeatable.

Conax solutions for Power Gen

EGTs for LM Series Land-Based Turbines

Conax exhaust gas sensors for LM6000 T4.8 turbines

- Conax uses state-of-the-art materials to achieve mechanical strength and oxidation resistance.

- The Conax Hermetic termination head utilizes type K termination studs that are sized so cables cannot be cross wired.

- The Conax solution is interchangeable with OEM products, so it can be used on all LM6000 applications.

- The LM6000 T4.8 over sheath is made from state-of-the-art material sized for proper fit around the thermocouple tip. The Conax design does not require special shims that can vibrate loose.

Conax EGTs for LM2500/LM5000

- Conax uses state-of-the-art materials to achieve mechanical strength and oxidation resistance.

- The Conax Hermetic termination head utilizes type K termination studs that are sized so cables cannot be cross wired.

- The Conax solution is interchangeable with OEM products, so it can be used on all LM2500 and LM5000 turbines.

Download our brochures

Download Exhaust Gas Thermocouples for LM2500 and LM5000 – Bulletin 6123

Download LM6000 T4.8 Exhaust Gas Thermocouple – Bulletin 6121

EGTs for FT8/GG8 Aeroderivative Ground-Based Engines

FT8/G8 users are choosing Conax Technologies’ exhaust gas thermocouples (EGT) over OEM sensors in their aeroderivative ground-based turbines. The innovative design in the Conax EGTs has proven to be more accurate and last longer than the OEM sensors. The key enhancement of Conax Technologies’ design is the use of two (2) dual thermocouple probes rather than four (4) single thermocouple probes. Conax employs unique manufacturing techniques to create balanced loop resistance between all thermocouples. The result is a more robust and reliable design that offers the same two (2) circuit, four (4) point averaging temperature measurements as an OEM sensor with superior accuracy and reliability. Here’s what sets the Conax EGTs apart:

- Superior design and quality

- Proven higher reliability than OEM sensors

- Hermetically sealed for high accuracy and long life

- Simple, quick installation that saves time

- Interchangeable with OEM sensors

- Typically in stock to provide quick turn around time

Download Exhaust Gas Thermocouples for Pratt & Whitney FT8/GG8 Frame E – Bulletin 6108

Exhaust Gas Thermocouples – OEM Replacements and Enhanced Designs

These type K ungrounded thermocouples are manufactured using Special (+/-0.4%) limits and have a time response of 1.7 to 4.0 seconds, depending on the tip configuration. Conax Technologies manufactures these exhaust thermocouples with tip diameters from .062 diameter to .125. They are used on all heavy-duty gas turbines and are of the latest configuration for easy replacement. Just connect our thermocouple to the flexible, stainless steel braided cable for quick installation and longer life.

All specification-qualified exhaust gas and blade path thermocouples are manufactured from ASTM E585 thermocouple materials utilizing the highest purity insulation material yielding superior insulation resistance at elevated temperatures.

The thermocouples are manufactured and tested at various points during the manufacturing cycle to ensure the highest possible level of quality. Product testing includes helium leak testing, calibration, thermal shock, insulation resistance and hermeticity testing of sealing points.

Featuring Type K conductor wire with MgO insulation, these sensors are hermetically sealed in stainless steel for high-temperature oxidation resistance and feature vibration-resistant hermetic terminations and high-reliability mineral insulated cable.

OEM Replacements

Download Exhaust Gas Thermocouples – bulletin 6054

Download Wheelspace and Exhaust Gas Thermocouples – bulletin 6052

Enhanced Designs

Download Enhanced Exhaust Gas Thermocouples – bulletin 6105

Download Highly Reliable Retrofit Exhaust Gas Sensors – bulletin 6064

Download Retrofit Blade Path Thermocouple Kit – bulletin 6067

Download Maintaining your Turbine just got Easier – bulletin 6112

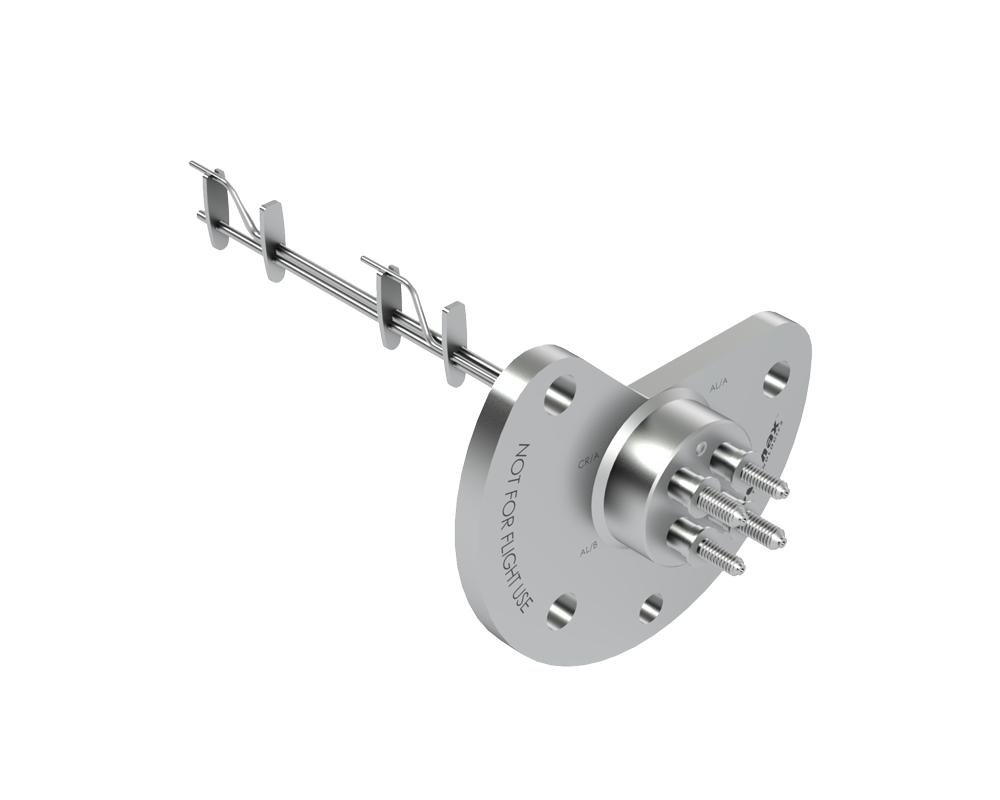

Air Inlet Thermocouples

All specification qualified air inlet thermocouples are manufactured from ASTM E585 thermocouple material utilizing the highest purity insulation material yielding superior insulation resistance and sensor repeatability. The thermocouples are manufactured and tested at various points during the manufacturing cycle ensuring the highest possible level of quality. Download Temperature Sensors and Seals for the Power Gen Industry

Wheelspace, Disc Cavity and Compressor Discharge Thermocouples

Conax Technologies’ thermocouples for this application meet the operational and performance requirements, per the OEM specifications, as replacements on heavy duty gas turbines. These cost-effective thermocouples are hermetically sealed to provide a more reliable product that eliminates IR failures. The positive stop at the tip of the thermocouple eliminates any fretting problems. Our wheelspace, disc cavity and CDT thermocouples are manufactured using a stainless steel sheath and MgO insulation with type K conductors to ensure the robust design needed in this application. All specification-qualified thermocouples are manufactured from ASTM E585 thermocouple material using the highest purity insulation material to yield superior insulation resistance at elevated temperatures. The thermocouples are manufactured and tested at various points during the manufacturing cycle, ensuring the highest possible level of quality. Production testing includes helium leak testing, calibration, thermal shock, insulation resistance, and hermeticity testing of sealing points. Download Wheelspace and Exhaust Gas Thermocouples Download Wheelspace Thermocouples

Bearing Sensors and Seals

The bearings of industrial rotating equipment operate under arduous conditions—often for considerable periods of time. The most reliable indicator of bearing condition is the temperature of the metal beneath the shoe. Recognition of rising temperature can provide a warning of the breakdown of the lubricating oil film, allowing machine shutdown and maintenance to take place before catastrophic failure of the bearing and possible damage to its mounting. Conax Miniature Bearing Sensors provide a simple and cost-effective method to monitor bearing temperatures. These sensors are for embedded applications where temperature monitoring is critical to machine performance and reliability. The unique bearing sensor wire seal prevents migration of oil along the sensor leads. Available with RTDs or thermocouple types J, K, T and E. Download Miniature Bearing Temperature Sensors

Cable and Harness Assemblies

Conax works directly with industry leaders to custom design, build, test, and deliver high-quality cable and harness assemblies for a wide variety of engines and applications, including:

- Cable assemblies for large frame ground-based turbines

- Cable and harness assemblies for ground-based aeroderivative engines

- Mineral insulated cable

The Quality Management System of Conax Technologies has been assessed by NSF-ISR, and Conax was the first in the industry to receive AS9100D certification.

Our patented Spring Loaded Exhaust Gas Sensors eliminate premature sensor failures

Standard exhaust gas sensors in 7F and 9F class turbines are at risk of premature failure due to vibrations caused by gas flow velocities, input vibrations and thermal expansion mismatch.

Conax Technologies’ exclusive Spring Loaded Exhaust Gas Sensors are specially designed to withstand these vibrations and avoid premature sensor failures.

Our patented sensors have a high temperature compression spring that’s inserted between two spacer tubes. The spring dampens the vibration and keeps the temperature sensor tip seated within the radiation shield. With this increased stability, the sensor tips won’t break. So turbines run longer without the risk of premature sensor failure.

View our video for a demo.