Conax engineers an electrode that results in a more robust reactor and improves safety for service technicians.

Industry: Photovoltaic

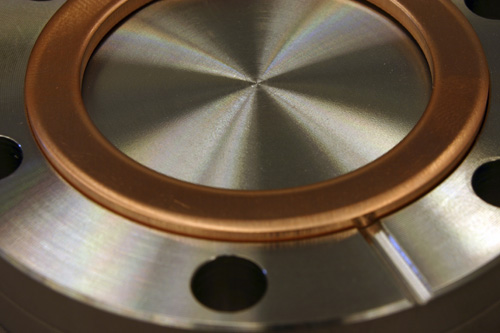

Challenge: A Conax client previously used a ceramic-to-metal seal flanged electrode that was delicate and cracked too easily. Due to deposition build up, there was also no easy way to remove the electrode. The usual practice was to cut the electrode off inside the reactor which caused particle generation, creating an unsafe environment for service technicians.

Solution: Conax designed an electrode that can pass through the flange assembly, so it may be removed safely simply by sliding it through the flange and into the reactor. This eliminates any cutting operations needed to remove the electrode and allows reuse of the flange/sealant assembly.

Impact: In addition to easy removal and improved safety for service technicians, this Conax solution eliminates the fragile ceramic-to-metal seal that previously cracked and failed, resulting in a more robust reactor.