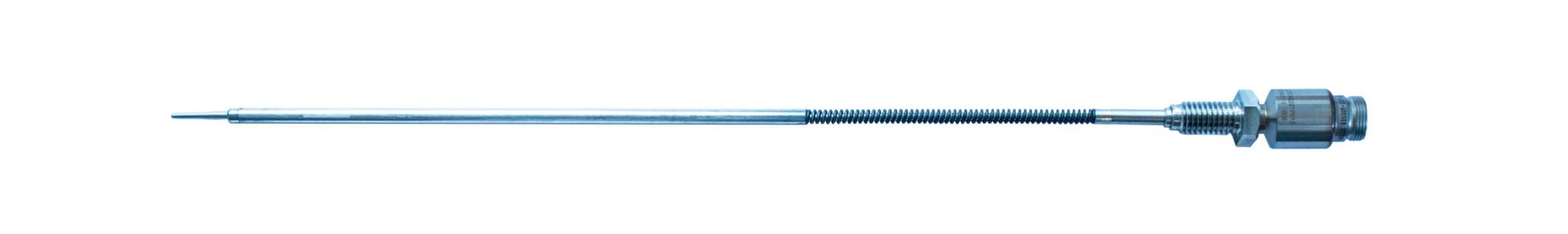

1950

Maurice W. Connell forms Conax Corporation, and first-year sales of his newly-patented high-speed thermocouple reach $9,000. Shown above is Joe Gennocro with the first Conax van.

1956

Conax Corp. begins construction of a new $200,000 plant at its current location on Walden Avenue in Buffalo, New York. The company’s existing workforce of 25 is projected to increase to 40 the following year. The primary products remain thermocouples used in jet engines and atomic submarines. However, Conax has already expanded its offerings to include pressure seals used by the military and in deep-sea exploration, as well as explosive-actuated valves for guided missiles.

1959

Conax begins work on a $100,000 addition to its new plant, adding 6,000 square feet to expand its manufacturing capabilities and provide office and engineering space for the company’s more than 70 employees.

1960

After 10 years, Conax Corporation’s annual sales volume reaches $2 million, with 120 employees serving 4,000 industrial customers worldwide.

February 20, 1962

Conax employees watch John Glenn orbit the Earth as part of NASA’s Project Mercury, knowing that explosive-actuated valves manufactured by Conax have played a role in the mission’s success. The company’s contribution to the mission is just the beginning of what will become a proud heritage in the aerospace industry for Conax.

Conax employees watch John Glenn orbit the Earth as part of NASA’s Project Mercury, knowing that explosive-actuated valves manufactured by Conax have played a role in the mission’s success. The company’s contribution to the mission is just the beginning of what will become a proud heritage in the aerospace industry for Conax.

1962

Conax designs and manufactures three small valves that play a major role in mid-course correction in the Mariner II spacecraft, whose mission was to fly within a distance of 10,000 miles of the planet Venus for various experiments—closer than any other device sent into space at that time.

1963

Based on the strength of Conax’s thermocouples for the atomic energy industry, foreign sales increase by 400 percent. With representatives/ distributors in Italy, France, Belgium and Spain, an expansion of the company’s European footprint is planned to include new offices in England, West Germany and the Netherlands.

June 1963

Conax breaks ground for a 10,000-square-foot expansion of its Walden Avenue plant.

April 1964

Conax buys the Morrison-International Equipment Division of Ryder System Inc., increasing the company’s non-military and non-industrial product offerings to include display cabinets, tire racks and portable refreshment stands.

June 1964

Conax acquires Beacon Devices Inc., a manufacturer of pressure cylinders and regulators, tire inflators and rescue torches. The company’s second acquisition of 1964 increases the number of employees to nearly 300 and puts Conax Corporation on pace for sales nearing $6 million in the 1964-65 fiscal year.

1965

Conax develops a CO2 beer tap for use in home refrigerators. Orders from breweries for more than 250,000 units are taken even before the product is on the market.

1968

Conax receives a patent for electrical penetration for nuclear applications. This patented electrical penetration became the standard bearer of the industry and remains so today, produced by Mirion Technologies.

1975

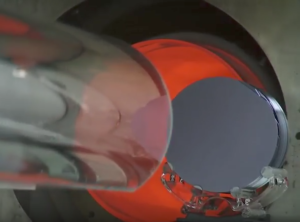

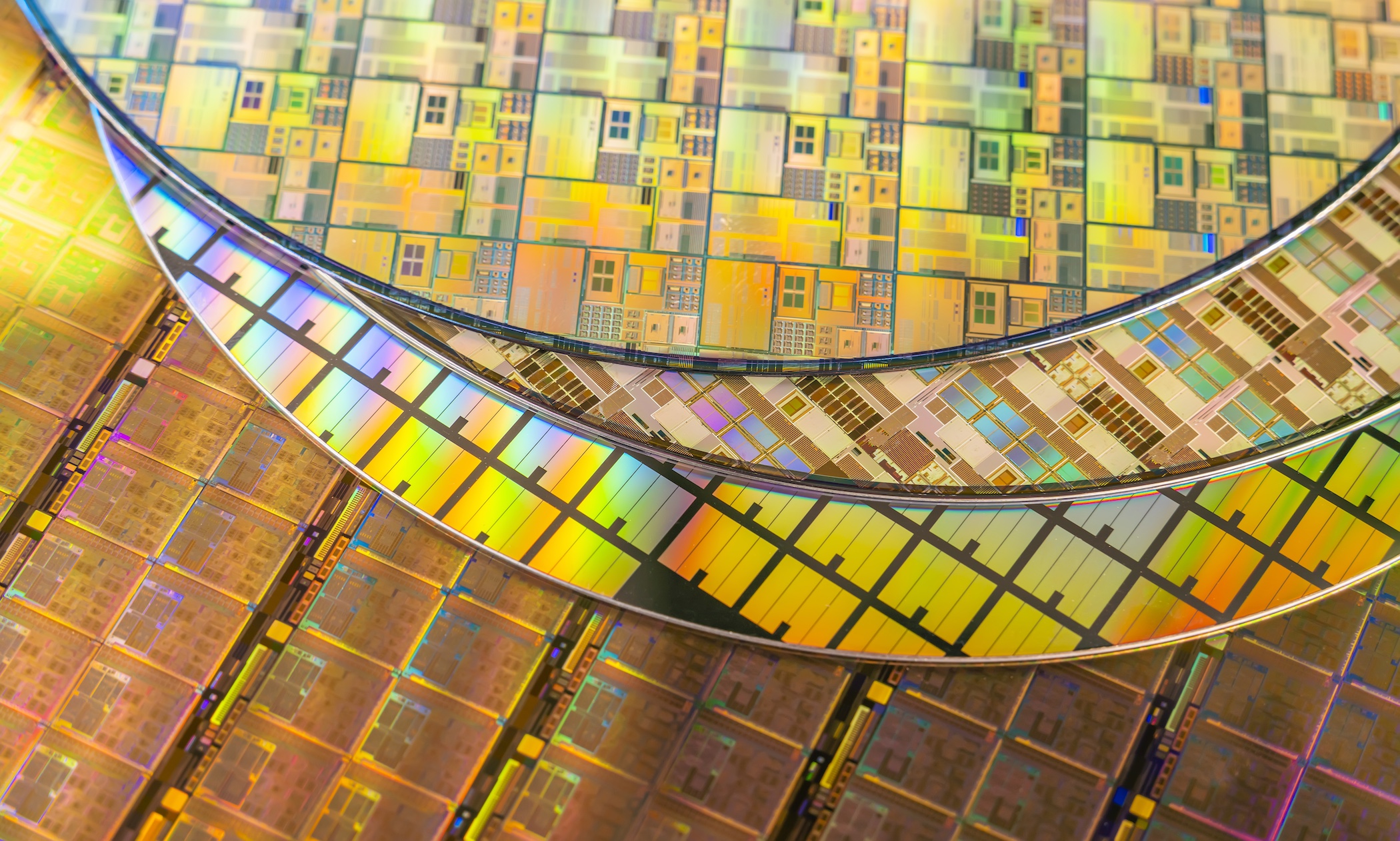

Applied Materials introduces the Epitaxial Barrel Reactor and selects Conax to supply the calibration thermocouple. The tool’s popularity helped establish Conax as a trusted partner in the epitaxial departments of wafer fabs worldwide.

1985

Conax is sold to New York M&A firm, Cortec Group.

1986

Conax Buffalo Corporation is awarded a patent for its Fiber Optic Temperature Sensor for extreme environments.

1988

Conax Buffalo Corporation is sold to Birmingham UK based IMIplc.

1997

Conax begins providing temperature sensors to EMCORE (now a division of Veeco) for their MOCVD reactors.

Intel seeks Conax’s help sealing on wiring to their HAST (Highly Accelerated Stress Test) chambers.

2000

Conax receives ISO 9001 quality management system certification—a designation that helps the company to be more competitive worldwide and to continually monitor and manage quality across all operations.

2005

Wafer Fabs turn to Conax as a supplier, providing quartz sheathed thermocouples for the ASM®‡ EPSILON®‡ epitaxial reactor.

Wafer Fabs turn to Conax as a supplier, providing quartz sheathed thermocouples for the ASM®‡ EPSILON®‡ epitaxial reactor.

‡ ASM® and EPSILON® are registered trademarks of ASM International. Neither Conax Technologies nor its products are affiliated with, licensed, approved by or sponsored by ASM International.

2006

Conax creates a separate group within the company to focus on products unique to the semiconductor industry; installs first laminar flow tables for Class 100 Cleanroom production.

Conax creates a separate group within the company to focus on products unique to the semiconductor industry; installs first laminar flow tables for Class 100 Cleanroom production.

2008

Conax adds a dedicated area for quartz sensor production on laminar flow tables.

2009

Conax begins to provide the semiconductor market with Profile and Spike thermocouples for many furnace manufacturers. These high-precision temperature sensors are engineered to address the critical process temperature measurement and control required for the semiconductor, solar and LED industries.

Conax begins to provide the semiconductor market with Profile and Spike thermocouples for many furnace manufacturers. These high-precision temperature sensors are engineered to address the critical process temperature measurement and control required for the semiconductor, solar and LED industries.

2011

Conax triples the size of its quartz sensor production facilities and laminar flow table production capacity.

2012

Conax opens its Shanghai sales office with a strong focus on the Asian semiconductor market.

Conax opens its Shanghai sales office with a strong focus on the Asian semiconductor market.

2015

Conax receives AS9100 certificate, meeting stringent quality management system requirements for the aviation, space, and defense industries. AS9100 encompasses ISO 9001, with additional requirements for quality and safety relevant to aerospace, and defines the quality management systems standard for the industry. All major aerospace manufacturers (OEMs) and suppliers worldwide endorse or require certificate to AS9100 as a condition of doing business with them.

2016

Conax purchases Quartz Engineering to better vertically integrate the production of quartz sheathed thermocouples for the semiconductor industry.

November 2016

Conax purchases a new state-of-the-art x-ray system that provides real-time x-ray views of parts and increased resolution 10X greater than the previous system. The new system enables parts to be repositioned to see the internal detail of interest.

December 20, 2016

Conax receives a Patent for the Spring-Loaded Exhaust Gas Sensor that eliminates premature failures in 7F and 9F class turbines. The new EGT is one of many unique and innovative solutions Conax has developed for the power generation industry.

2017

Conax introduces EtchDefender™, a quartz coating that significantly increases quartz life in high-temperature, highly-corrosive semiconductor reaction chamber environments.

July 2018

To accelerate the pace of their continued growth in the semiconductor industry, Conax Technologies moves their Arizona facility to a new, modern facility in Tempe, AZ, featuring expanded office space, an improved production area, and increased annealing capabilities.

October 2018

Conax gains reaccreditation to revision D, AS9100D certificate. All major aerospace manufacturers (OEMs) and suppliers worldwide endorse or require AS9100 certification as a condition of doing business with them. The update incorporates changes to the ISO 9001:2015 and addresses industry and stakeholder needs.

February 2020

Conax introduces a new exhaust gas thermocouple for FT8 turbines that utilizes two dual circuit ungrounded thermocouple probes versus the OEM version utilizing four single thermocouple probes. The superior design results in a thermocouple that lasts longer and is more accurate over time than the OEM’s product.

March 2020

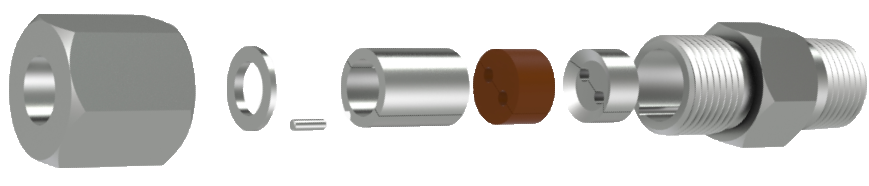

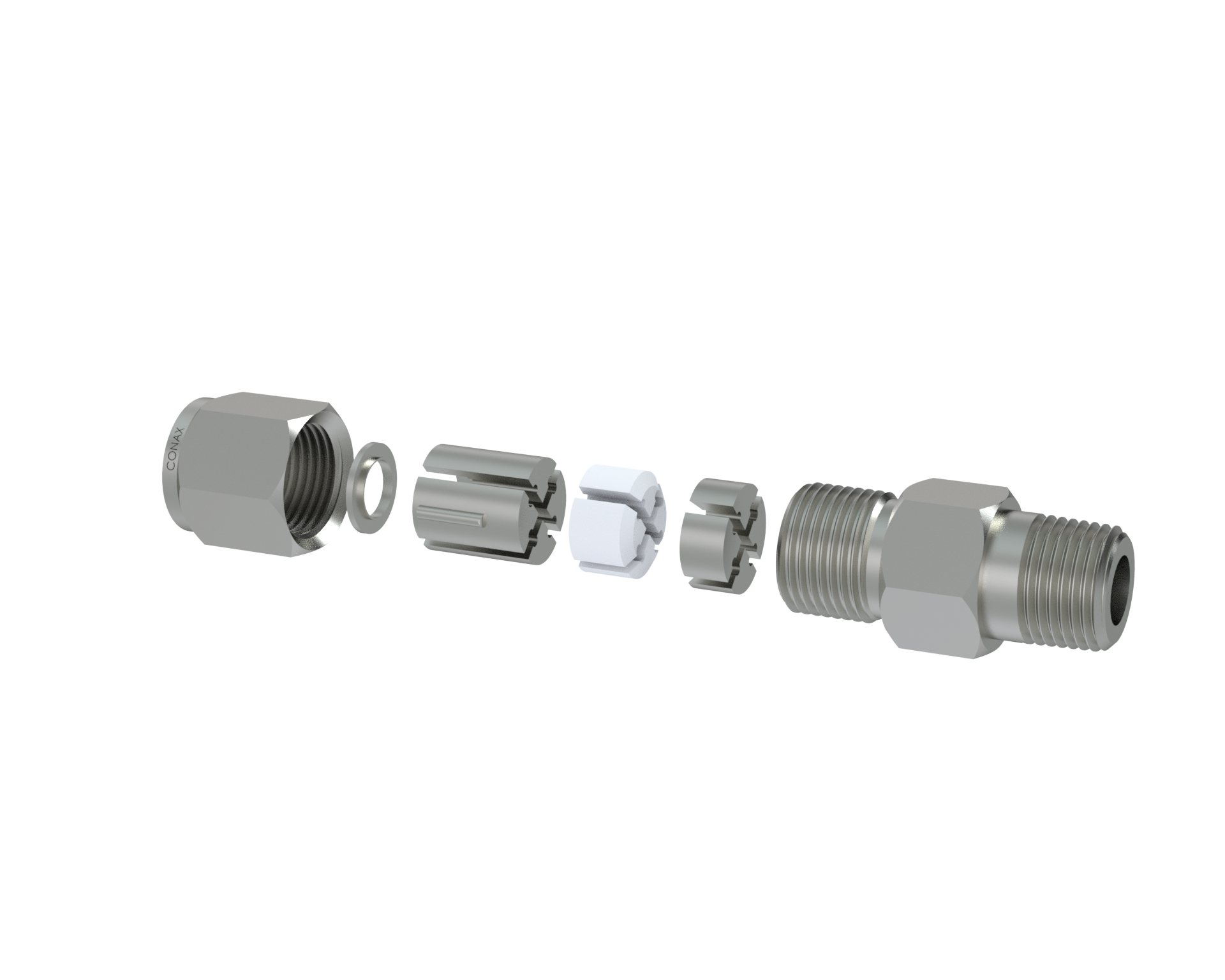

Conax Technologies introduces multi-hole fittings featuring an integral pin that is machined into the follower to make assembly faster, easier and safer.

April 2020

Conax develops SPGA fittings carrying both hydraulic and pneumatic catalog pressure ratings that seal on multiple elements with a single split.

July 2020

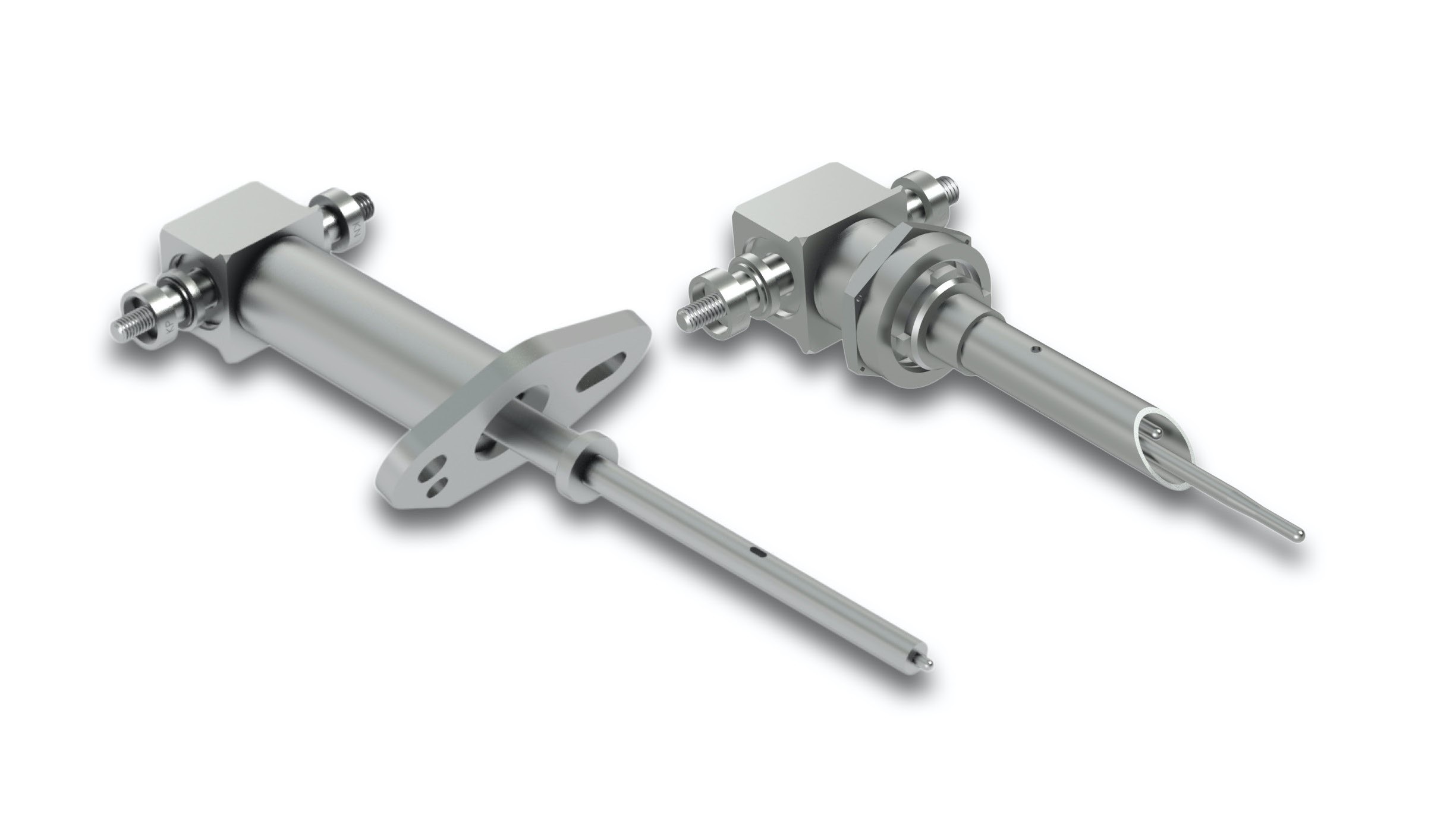

Conax Technologies develops the Wake Frequency Solution Builder™, an online tool that enables engineers to conduct Wake Frequency calculations for Sample Probe Assemblies (SPAs) prior to manufacturing. Engineers can get fast confirmation for each design element that passes and immediately identify design flaws that don’t meet standards.

July 2020

Conax continues to develop innovative solutions for the power generation industry, introducing competitively-priced, aftermarket exhaust gas sensors for large frame and aeroderivative ground-based turbines. The new solutions for LM6000 T4.8 and LM2500/LM5000 engines are engineered with state-of-the-art materials and are fully interchangeable with OEM products.

February 2021

Conax receives ISO/IEC 17025:2017 Accreditation, officially recognizing the Conax calibration laboratory as fully capable and competent. ISO/IEC 17025:2017 sets the national standard of excellence for the competence of testing and calibration laboratories, and accreditation assures customers that Conax will produce valid and reliable results.

Conax receives ISO/IEC 17025:2017 Accreditation, officially recognizing the Conax calibration laboratory as fully capable and competent. ISO/IEC 17025:2017 sets the national standard of excellence for the competence of testing and calibration laboratories, and accreditation assures customers that Conax will produce valid and reliable results.

August 2021

Conax Technologies receives Nadcap accreditation signifying that the companies’ operations meet AC7121 audit criteria for electronics in the manufacture of cable and harness assemblies. Nadcap (National Aerospace and Defense Contractors Accreditation Program) is a globally-recognized accreditation program, driven by a stringent set of quality assurance standards that have been established by the consensus of experts from both the government and private industry.

November 2021

Conax receives a Patent for EtchDefender™ Technology that extends the life of quartz thermocouple sheaths in certain epitaxial reactors. The patented solution is just one of the many cutting-edge solutions Conax provides to the semiconductor industry.

December 2021

Conax adds DSPGA fittings to its line of multi-hole split seal fittings that carry both hydraulic and pneumatic catalog pressure ratings. DSPGA assemblies seal on multiple elements with a double split.

May 2022

Conax Technologies introduces LeakDefender™ brand thermocouples that provide real-time monitoring for gas leaks to minimize wafter loss and maximize TC life.

November 2022

Photo courtesy of NASA/Bill Ingalls

Conax partners with NASA in the Artemis 1 mission. Components designed and manufactured by Conax Technologies were used on the Orion spacecraft that traveled over 1.3 million miles over 25 days orbiting the moon.

December 2023

Conax Technologies is added as a voting member for the Nadcap® program and is awarded Nadcap® Merit status in recognition of superior performance and commitment to continual improvement in aerospace quality.