Description

Exhaust Gas Sensor

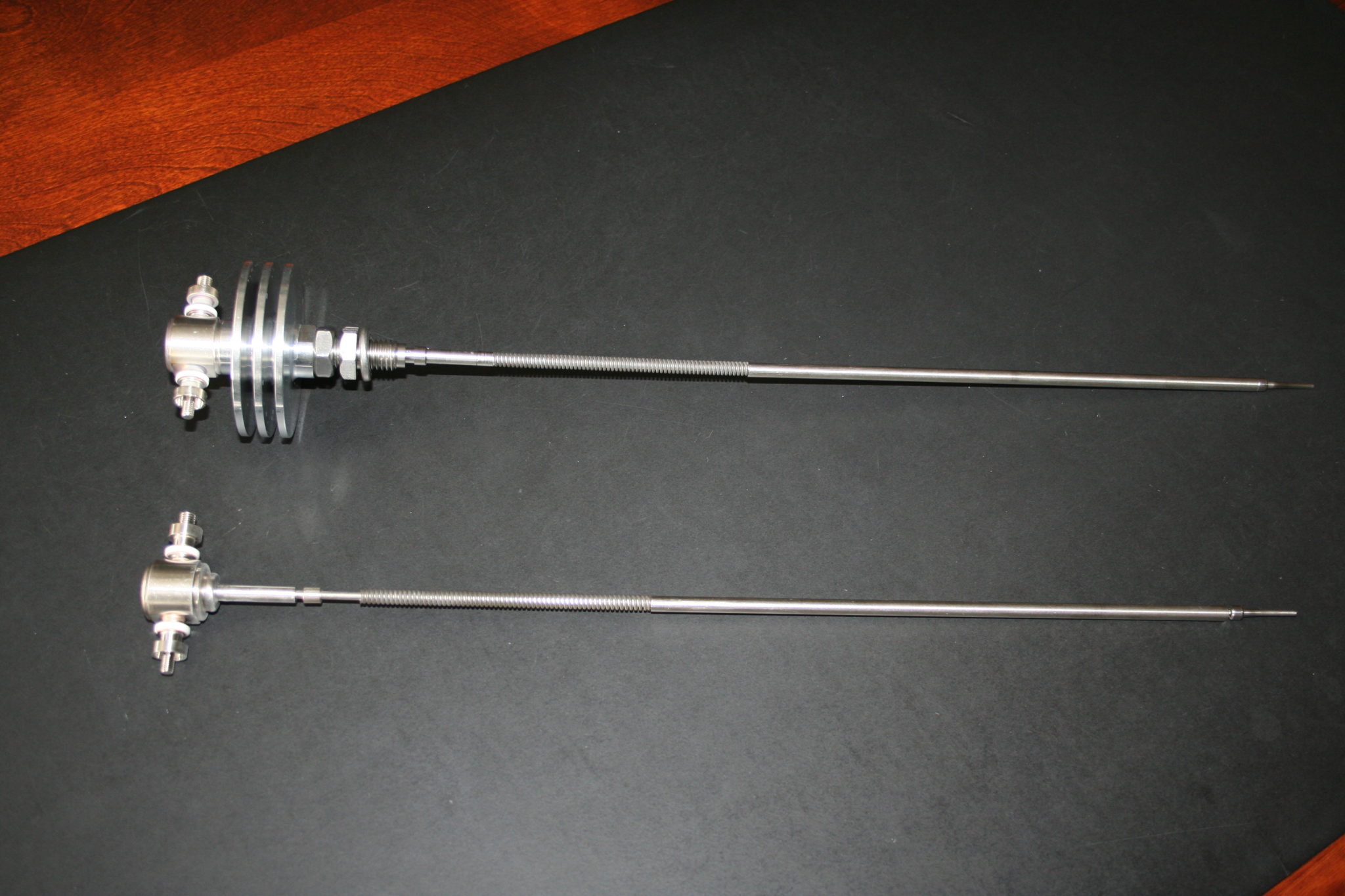

Exhaust Gas Sensors and Blade Path Sensors

These type K ungrounded thermocouples are manufactured using Special (+/-0.4%) limits and have a time response of 1.7 to 4.0 seconds depending on the tip configuration. Conax Technologies manufactures these exhaust thermocouples with tip diameters from .062 diameter to .125. They are used on all heavy duty gas turbines and are of the latest configuration for easy replacement. Just connect Conax’s thermocouple to the flexible, stainless steel braided cable for quick installation and longer life.

Blade Path Sensor

All specification qualified exhaust gas and blade path thermocouples are manufactured from ASTM E585 thermocouple materials utilizing the highest purity insulation material yielding superior insulation resistance at elevated temperatures.

The thermocouples are manufactured and tested at various points during the manufacturing cycle ensuring the highest possible level of quality. Product testing includes helium leak testing, calibration, thermal shock, insulation resistance and hermeticity testing of sealing points.

Frame 5 Series EGT Sensor

Featuring Type K conductor wire with MgO insulation, hermetically sealed in stainless steel for high-temperature oxidation resistance, vibration resistant hermetic terminations and high reliability mineral insulated cable.

Conax Technologies also manufactures exhaust thermocouples using other configurations. Simply supply the drawing number you have and utilize our short cycle turn around time.

These exhaust gas thermocouples, like all of our products, are manufactured in the United States of America.

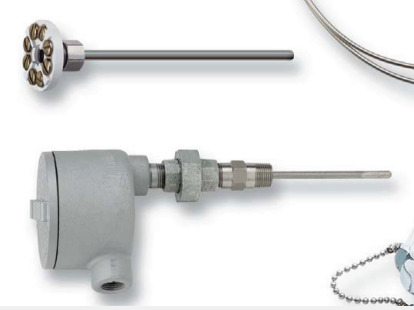

Wheelspace, Disc Cavity and Compressor Discharges Thermocouples

Frame 7 Series EGT Sensor

Conax Technologies’ thermocouples for this application meet the operational and performance requirements per the OEM specifications as replacements on heavy duty gas turbines. These cost effective thermocouples are designed to be hermetically sealed to provide a more reliable product that eliminates IR failures. The positive stop at the tip of the thermocouple eliminates any fretting problems. Conax’s wheelspace, disc cavity and C.D.T. thermocouples are manufactured using a stainless steel sheath, MgO insulation with type K conductors to ensure the robust design needed in this application.

Wheel space Sensor Assembly

All specifications qualified thermocouples are manufactured from ASTM E585 thermocouple material utilizing the highest purity insulation materials yielding superior insulation resistance at elevated temperatures. The thermocouples are manufactured and tested at various points during the manufacturing cycle, ensuring the highest possible level of quality.

Production testing includes helium leak testing, calibration, thermal shock, insulation resistance and hermeticity testing of sealing points. Conax Technologies also manufactures these type thermocouples using other configurations. Simply supply the drawing number you have and utilize our short cycle turn around time.

These thermocouples, like all of our products, are manufactured in the United States of America.

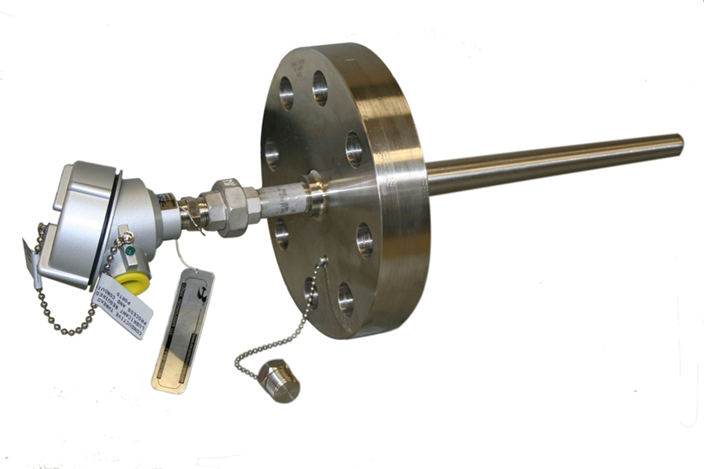

Bearing Sensor Assembly

Bearing Sensors and Seals

These sensors are for embedded applications where temperature monitoring is critical to machine performance and reliability. Available with RTDs or thermocouple types J, K, T and E. The unique bearing sensor wire seal prevents migration of oil along the sensor leads.

Air Inlet or Oil Temperature Sensor

Air Inlet or Oil Temperature Sensor

All specification qualified air inlet thermocouples are manufactured from ASTM E585 thermocouple material utilizing the highest purity insulation material yielding superior insulation resistance and sensor repeatability. The thermocouples are manufactured and tested at various points during the manufacturing cycle ensuring the highest possible level of quality.