Challenge:

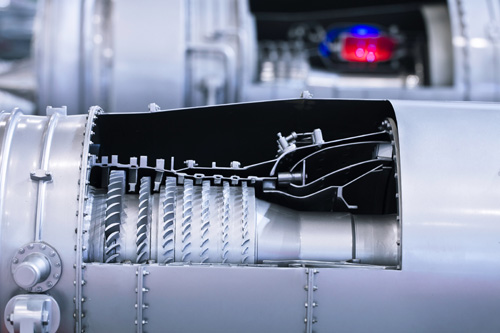

A Conax customer needed a source for flashback thermocouples on a Siemens Westinghouse W501F gas turbine. They currently have four turbines with plans to bring two more on line in the future. Each turbine has 16 burner cans with two sensors on each burner can for a total of 32 sensors. They schedule maintenance once or twice per year, but unscheduled outages also occur.

The sensor assemblies use Type K sensor elements, with grounded junction and 316SST sheath, and operate at 700°F. Positioning of the sensor within the burner can is critical. If the sensor tip is off by 1/2” either direction, a massive error in temperature results. They purchased the sensors from a local distributor, but were hoping to find a lower cost alternative.

Solution: Conax provided the desired cost savings while enhancing the design, shortening the sensor length to better fit the turbine.

Impact: We understand their business enough to refine the design to meet their needs. Conax expertise and design capability led to a subsequent quote on disk cavity thermocouples for the same turbines.