Description

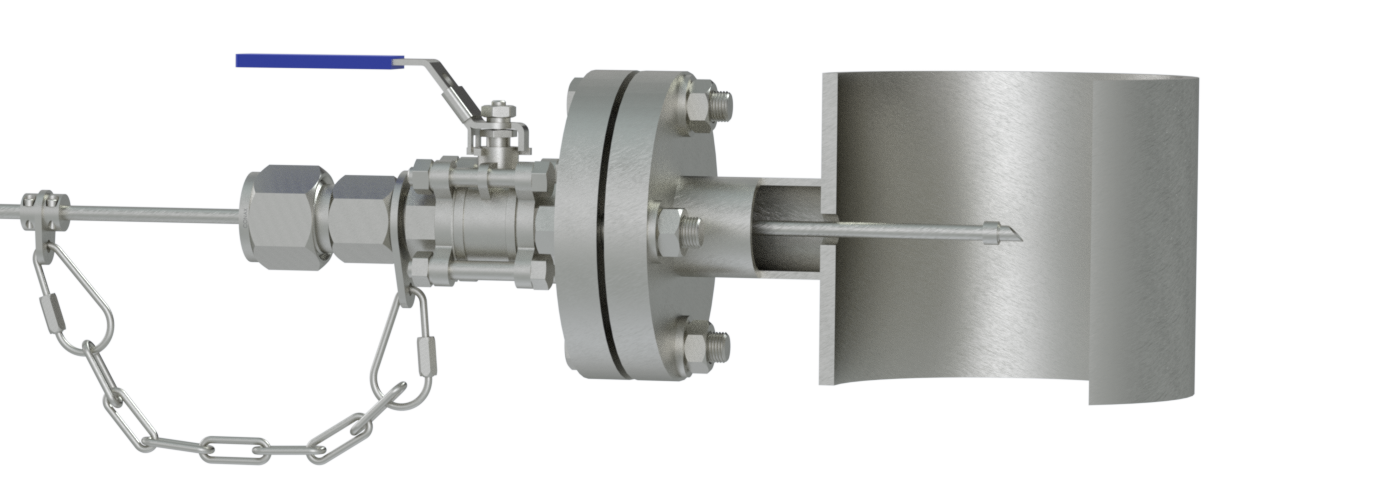

Sample Probe Assemblies (SPAs)

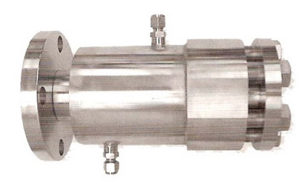

Conax Technologies’ Sample Probe Assemblies (SPA) are used to insert and retract an analyzer sample probe or injection quill into a pressurized process through a process isolation valve. Conax SPAs are designed for unique applications, including:

- Process analysis

- Flare stack emissions

- Chemical injection quills

- Waste water analysis

- Potable water quality sampling

- Hot tapping liquid or gas streams

Conax features

- Plasma welded stop collar

- Retaining Chain Kit

- Wake frequency calculations through our online Wake Frequency Solution Builder™

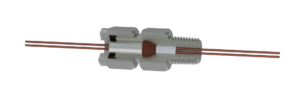

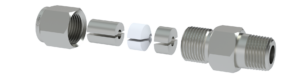

- Various probe ends and valve types available

Material options

- Optional materials for the Sample Probe Assembly and the Conax Compression Seal Fitting (PG) body (wetted components) are available. Available options include 316L SST, 316 NACE SST, 316L CRN, Monel 405, Hastelloy C276, Inconel 600 and others.

- Sample Probe Assemblies and/or PG fitting bodies can be supplied with a Silcolloy™ 1000 (Silcosteel®-CR) or SilcoNert™ 2000 (Siltek®/Sulfinert®)coating.

- Standard Sealants are PTFE and Grafoil®. Other sealants are available for special applications.

Ensure your SPA meets ASME and IEC standards

Conax Technologies’ SPA Quote Request form is available to identify the full range of process conditions Conax requires to develop a design solution. Please complete this form and email it to [email protected]. If you need engineering help to ensure you’re choosing the proper Sample Probe Assembly (SPA) for a specific application, we’ve created the Wake Frequency Solution Builder™ to generate immediate, online wake frequency calculations. This tool enables you to enter data for the specific SPA you need and receive immediate calculation results, based on ASME PTC 19.3 TW-2010 and/or IEC/TR 61831 standards. If there are problems with the configuration of your SPA, you’ll see exactly what needs to be adjusted. If the design is approved, you’ll see confirmation that each element tested has passed, and you can contact us to purchase the SPA.