Conax provided a custom-designed hybrid of its EG feedthrough allowing for the thermal systems heater power feedthrough to be rebuilt in the field reducing the loss of productivity found with the Wellman Design.

Industry: Aerospace

Company: Aerospace Composite Parts Manufacturer

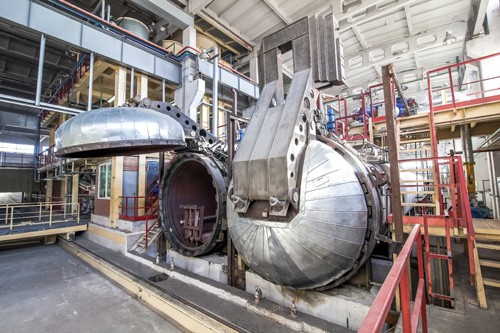

Challenge: The Conax customer requested a replacement for its Wellman Thermal Systems Heater Power Feedthrough in an aerospace parts autoclave. The existing design required a complete offsite rebuild over several months with a significant loss of productivity and a continuous performance degradation throughout its life cycle. They requested a solution that provided reduced cycle time and reduced down time.

Solution: Conax developed a “plug and play” solution through a custom-designed hybrid of our EG feedthrough and our EGT feedthrough designs. We combined positive features of each feedthrough, offering several key advantages compared to the Wellman Design, the most important of which allows the product to be rebuilt in the field for optimal performance.

Other benefits of the design include:

- High temperature resistance required closer to the heaters.

- Incorporates more robust, less costly components for the balance of the assembly located where lower temperatures prevail.

- Specially made solid nickel conductors designed with staggered lengths to ease power cable attachment.

Impact: The custom design allows the heating elements to function at peak performance at all times, reducing cycle times and down time. The few replacement parts required can be replaced on-site in the time it takes for the unit to cool down and be reloaded with new production material. As such, the customer experienced performance and longevity improvement.