Description

CBT 100, CBT 200 CBT 300 and CT 600 Series assemblies meet U.S. and Canadian standards (NRTL/C, CSA) for use in hazardous locations as defined by NEC Class 1, Division 1, Groups B, C & D; Class II, Groups E, F & G; and Class III.

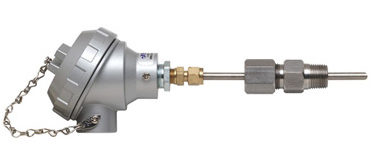

CBT 100 Series sensor-terminal head assemblies are available in all thermocouple calibrations and in RTD assemblies with 100, 200, 500 and 1000 ohm platinum, 10 ohm copper or 120 ohm nickel elements. Assemblies are available with stainless steel sheaths, a W8 mounting fitting and explosion-proof terminal head with terminal strip and 4-20mA transmitter.

|

| Example: CBT100-RTD43W3-SS25-T8E(W8)-15.00″ |

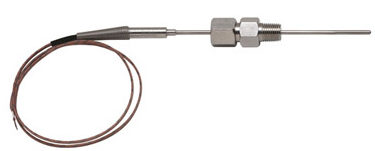

CBT 200 and CBT 300 assemblies are NEC-compliant replacement probes for use with UL and CSA-approved terminal heads in hazardous locations. CBT 200 provides a W8 fitting for attachment to the terminal head and to the vessel. CBT 300 provides a W7 fitting for attachment to the terminal head. A separate adjustable fitting is required to attach the probe to the vessel.

|

|

| Example: CBT200-RTD43W3-SS25-T1(4”)-W8-15.00″ | Example: CBT300-RTD43W3-SS25-T1(4:)-W7-15.00″ |

CT 600 Series sensor-terminal head assemblies are available in all thermocouple calibrations and in RTD assemblies with 100, 200, 500 and 1000 ohm platinum, 10 ohm copper or 120 ohm nickel elements. Assemblies are available with stainless steel or Inconel sheaths, a spring loaded mounting fitting (CSLW) and explosion-proof terminal head with terminal strip. Note: Sensor must be installed into either a thermowell or a port machined into a solid metal piece with a 1/2″-14 NPT mounting connection made per ANSI/ASME B1.20.1 and gauged to +1/2 to +2 turns from flush with end of start thread in accordance with CSA Std. C22.2 0.5 and UL Std. 1203, A 36″ maximum bore depth, a 0.104″ minimum wall, and a ∅0.302″ maximum bore.

|

| Example: CT600-RTD43W3-SS25-T8E(CSLW) -15.00” |

Certificate No. LR111664-1