Conaxioms

Conax solutions for fuel cells and energy storage technology

Innovative ideas that fuel a cleaner world Fuel cell technology plays a vital role in helping to...

Exploring the economic potential of energy storage in the U.S. power sector

Energy storage deployment is forecast to increase significantly through 2050 In a June article,...

Hydrogen is fueling the future of mobility

The impact of hydrogen fuel cell technology on logistics and commercial transportation The...

Visit Conax June 17 & 18, 2021 in Shanghai China

Conax will attend the 5th Annual Commercial Aero Engine Shanghai International Forum Conax...

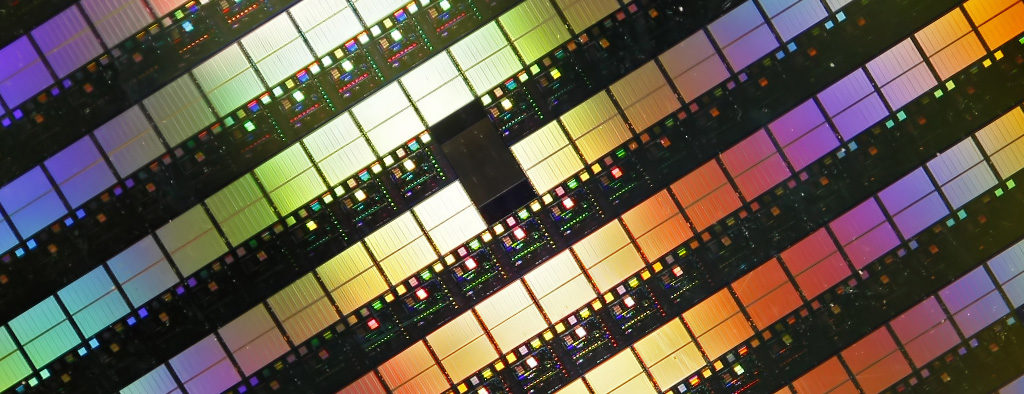

GlobalFoundries to move HQ to upstate New York

A recent article at compoundsemiconductor.net provided details on GlobalFoundries’ decision to...

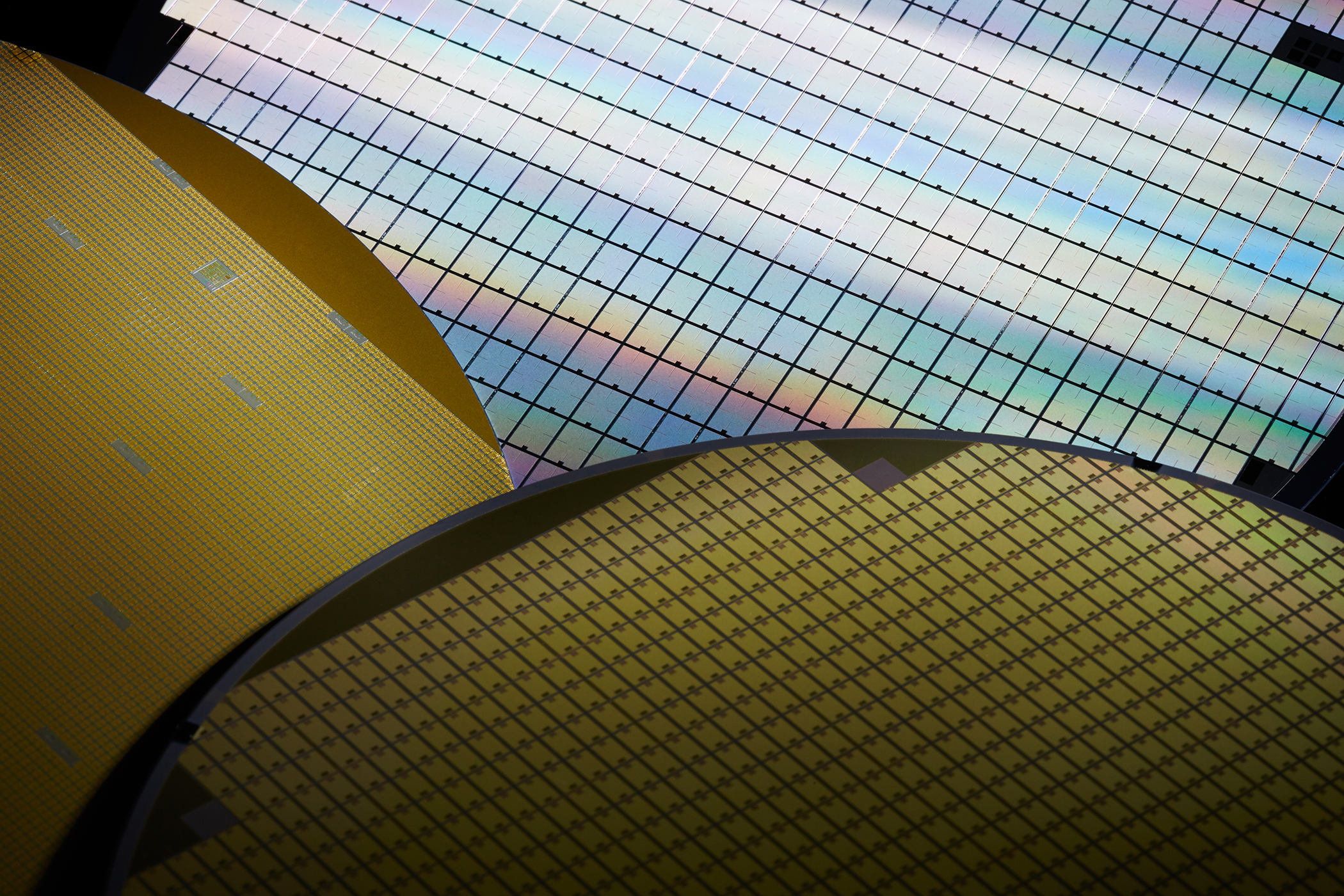

Advances in semiconductor technology helped ease the transition for a global remote workforce

Thanks for helping us get ahead in the cloud In a recent article at semi.org, ESD Alliance...

Staying compliant with latest revisions to heat treating specifications

AMS 2750F expands pyrometry requirements for calibration and testing Aerospace Material...

Get our guide to proper thermocouple and RTD sensor assembly installation

Our Field Installation Guide helps ensure successful operation If you purchase temperature...

Conax to exhibit at SEMICON China March 17-19, 2021

Visit Conax at Booth E7579 Conax Technologies is looking forward once again to attending and...

President Biden signs executive orders to address semiconductor chip shortage

COVID-19’s impact on semiconductor production The COVID-19 pandemic unveiled just how fragile the...