Conaxioms

Introducing two new Conax team members

Conax Technologies is pleased to introduce two new team members. Harneet Singh has been hired as...

Customized cable and harness assemblies for aerospace

For more than 70 years, customers in the aerospace industry have counted on Conax Technologies to...

Two safety devices that protect downed pilots have a Conax connection

Recently, a U.S. Navy pilot was rescued after ejecting from his aircraft near Key West, Florida....

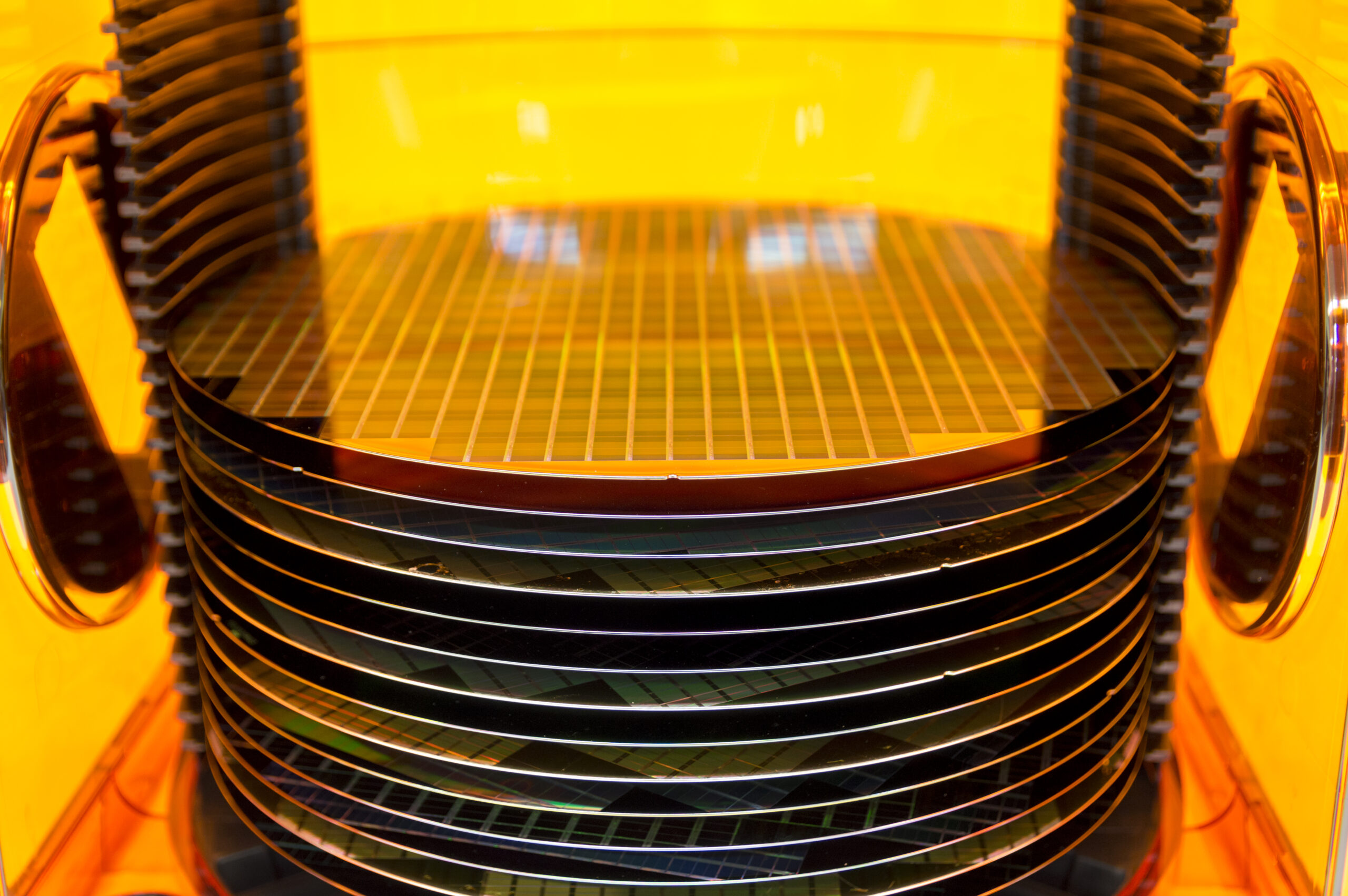

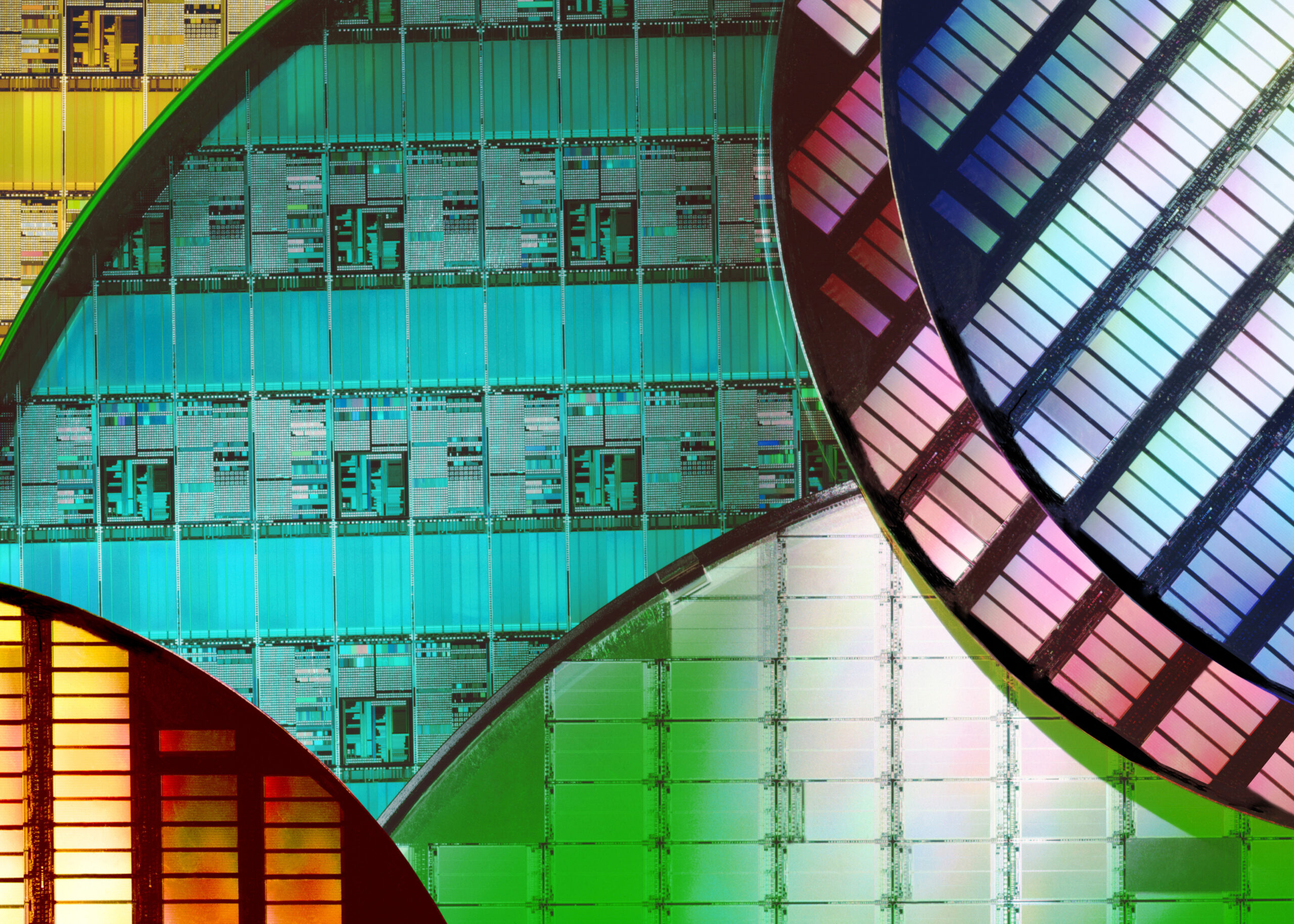

13 new 300mm wafer fabs to be brought online in 2023

A total of 180 300mm fabs will be operating by the end of the year According to a recent...

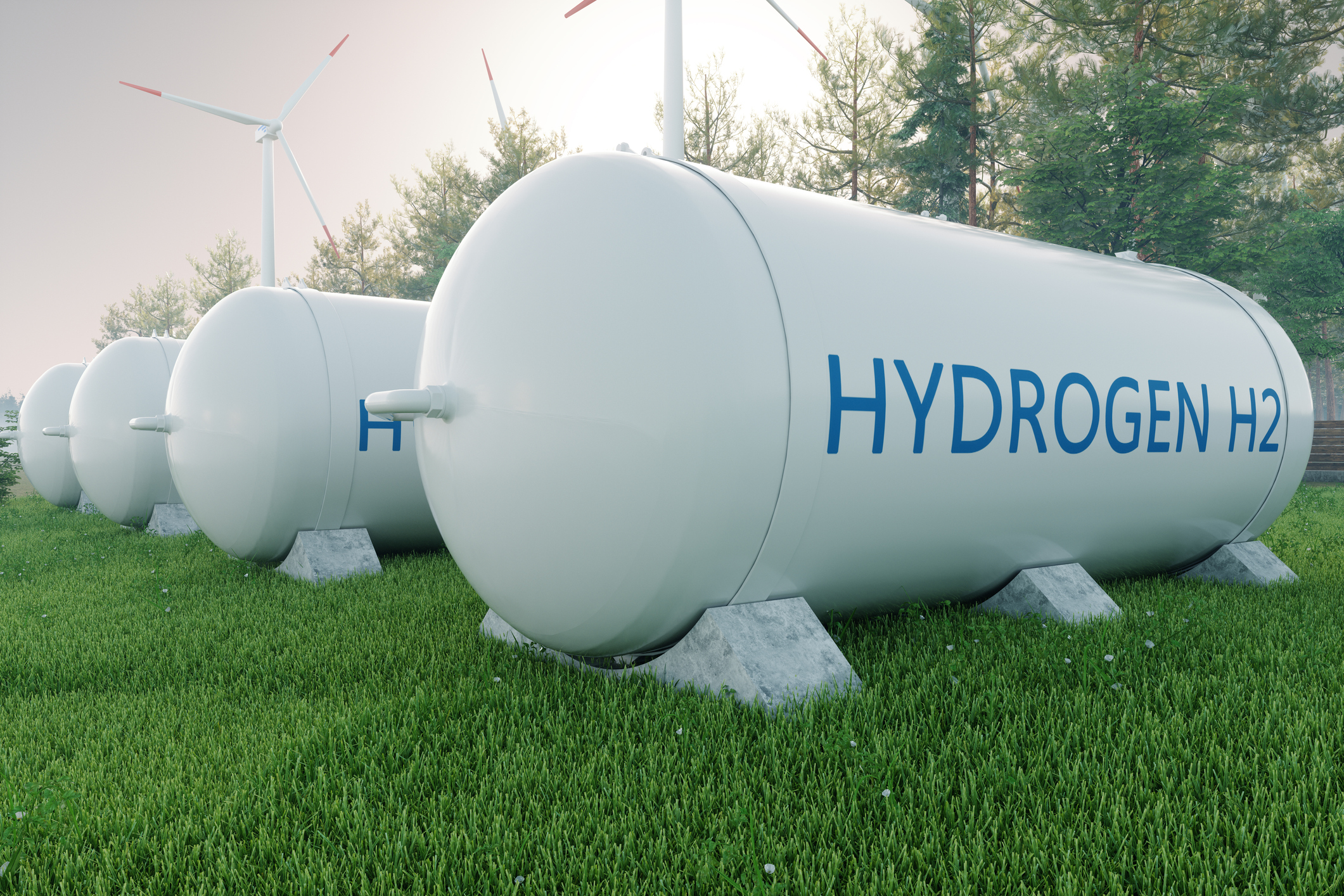

Japan earmarks $107 billion for developing hydrogen energy

Japan’s government recently revised and updated the country’s plans to increase hydrogen fuel...

Conax Technologies to exhibit at SEMICON China June 29 – July 1

Visit Conax at Booth #E5248 to learn about our exclusive solutions for semiconductor Conax will be...

5 ways to boost chip production in the US and EU

Regaining their lost share of global chip manufacturing Over the past 30 years, the chip...

Conax Technologies is growing

We’ve added two experienced Business Development Managers to our team We’re pleased to introduce...

Connect with Conax at the 7F Users Group

See our patented Spring Loaded Exhaust Gas Sensors Conax Technologies will be in Atlanta May 15th...

See our tightest split seal fittings ever in this 60-second video

Higher pressure ratings than standard multi-hole fittings Conax Technologies offers SPGA and DSPGA...