Conaxioms

Order now for the Power Generation spring outage season

Avoid last minute rush orders and possible delays If you’re planning to place an order for an...

Visit our booth at the 501F Users Group Conference

View Conax Technologies’ standard and custom solutions for 501F&G users If you’re attending...

Conax receives ISO/IEC 17025:2017 accreditation

Calibration lab accreditation expands our capabilities Conax Technologies’ is proud to announce...

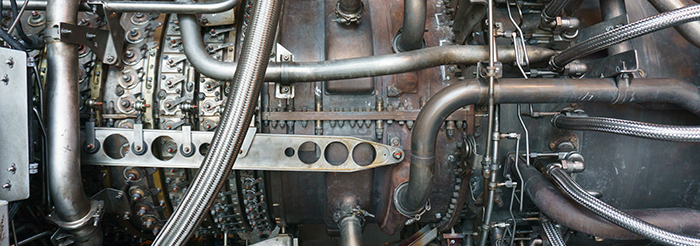

Solutions for aerospace, power and more

Sensors and cable and harness assemblies Customized solutions for a broad range of industries and...

Cost-effective solutions for LM Series turbines

Conax exhaust gas sensors for large frame and aeroderivative ground-based turbines Conax...

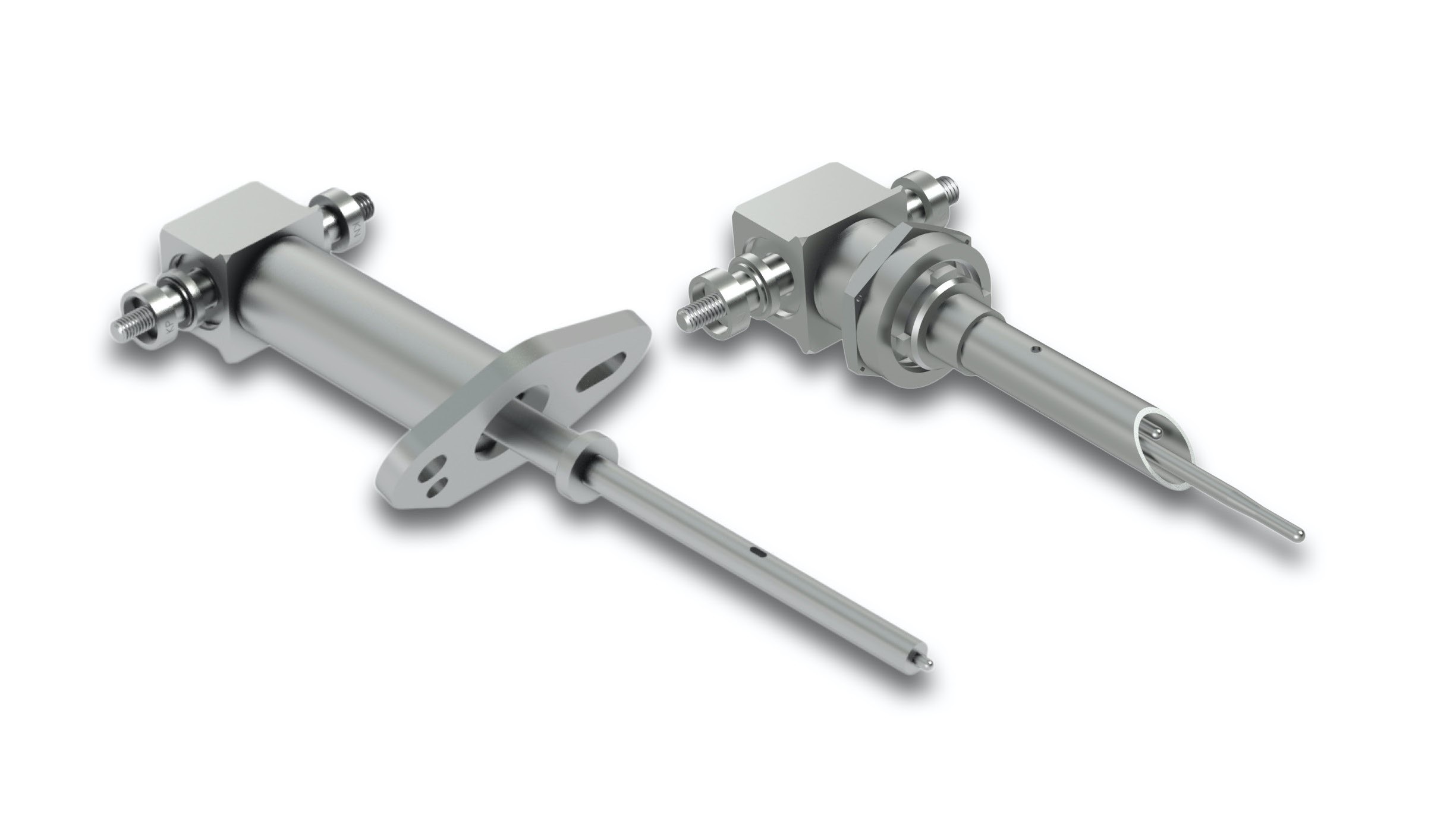

Our SPGA split seal fitting has catalog pressure ratings

Conax now offers the SPGA with higher pressure ratings than standard split seal fittings The...

300mm fab spending to increase through 2023

According to SEMI’s 300mm Fab Outlook to 2024 report, 300mm fab investments in 2020 will grow by...

Conax to attend 6th Annual Aeronautical Materials and Manufacturing Technology Shanghai International Forum

Conax will be attending the Aeronautical Materials and Manufacturing Technology International...

43 percent of U.S. power generation is from gas-fired power plants

According to a new report from the federal Energy Information Administration (EIA), gas-fired...

10 Tips to Ensure Accurate Thermocouple Measurement

Download our brochure From choosing the right sensor for your particular process application to...