Conaxioms

Conax to attend the Civil Aircraft Operation Support Technology International Forum 2020

Highlighting a rich heritage in the aerospace industry Conax Technologies will be attending the...

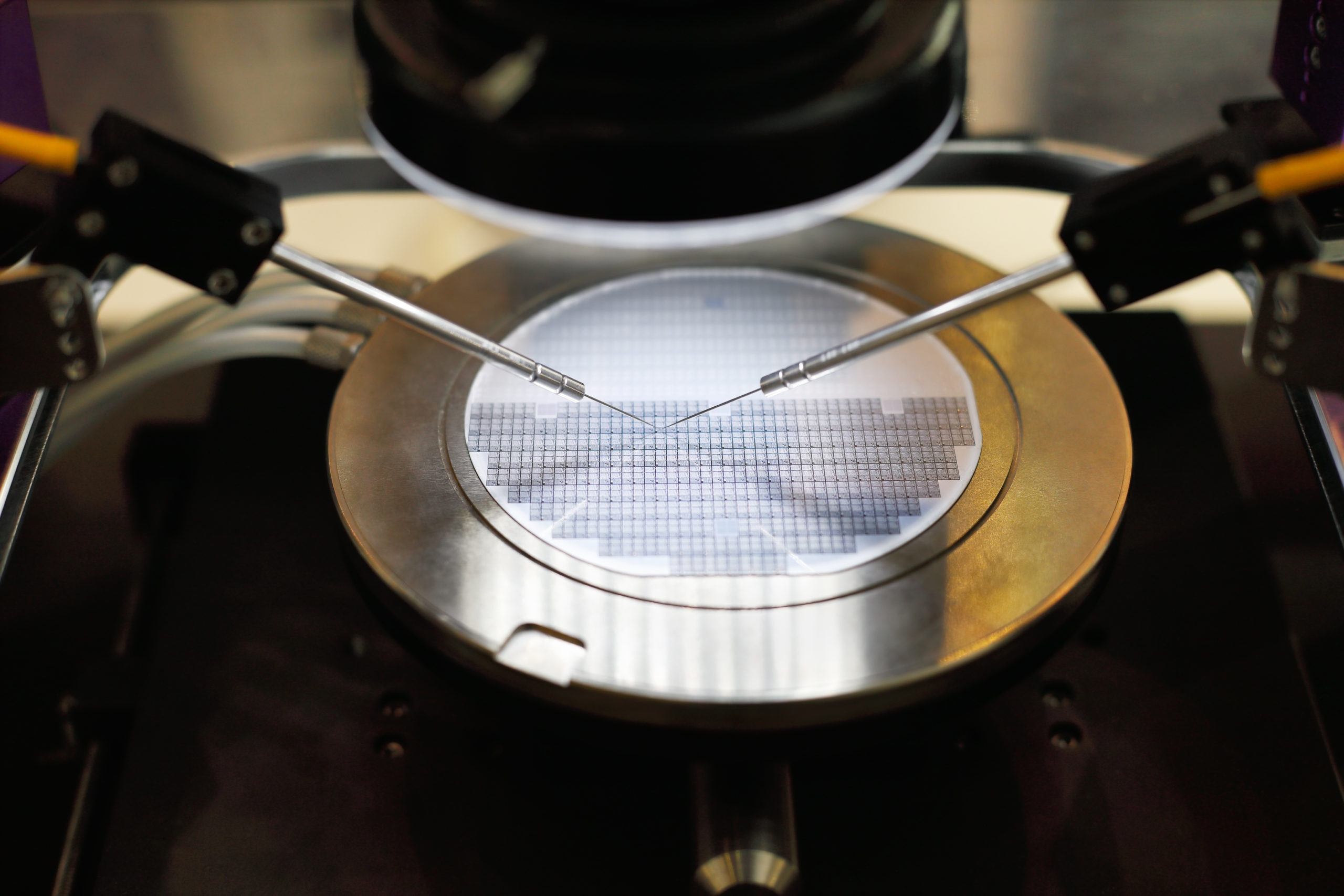

America’s lead in chip technology is eroding

Learn about increased efforts to revive U.S. chip manufacturing A recent article in EE|Times...

Partner spotlight: First Solar

Conax is proud to partner with First Solar—one of the world’s leading solar manufacturers Conax...

Get the latest news on heat treating solutions from Conax at FNA 2020

We’re looking forward to the upcoming Furnaces North America (FNA) 2020 Virtual Trade Show and...

Time is running out for fall outage season orders

Order now to avoid rush orders and possible delays Conax Technologies is geared up and ready to...

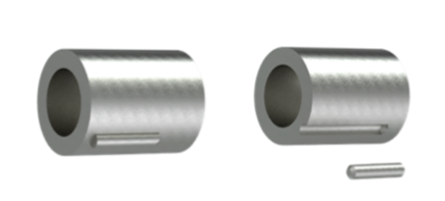

Our multi-hole metal fittings are now easier to assemble

Multi-hole metal compression seal fittings now with integral pin Conax Technologies has already...

Are you ready for the fall outage season?

Order your sensors now to stay ahead of peak demand Conax Technologies is geared up and ready to...

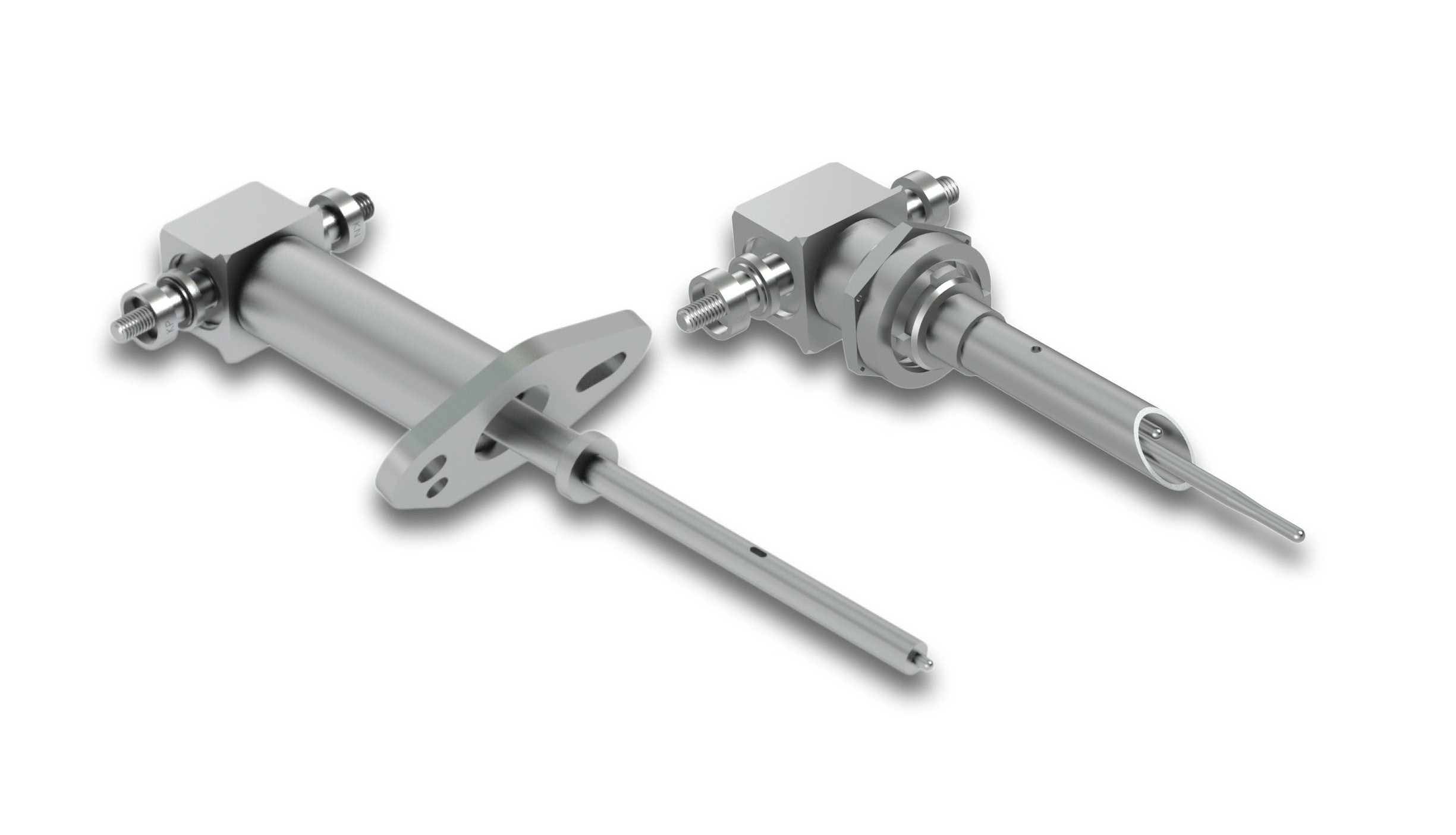

Visit Conax at the CTOTF Virtual Conference and Tradeshow August 24th – 27th

Visit our virtual booth for cost-effective solutions for large frame and aeroderivative...

2021 NDAA Fiscal Year Approval – Incentives to Grow Semiconductor Manufacturing and Research

The United States House of Representatives and Senate included amendments in the Fiscal Year 2021...

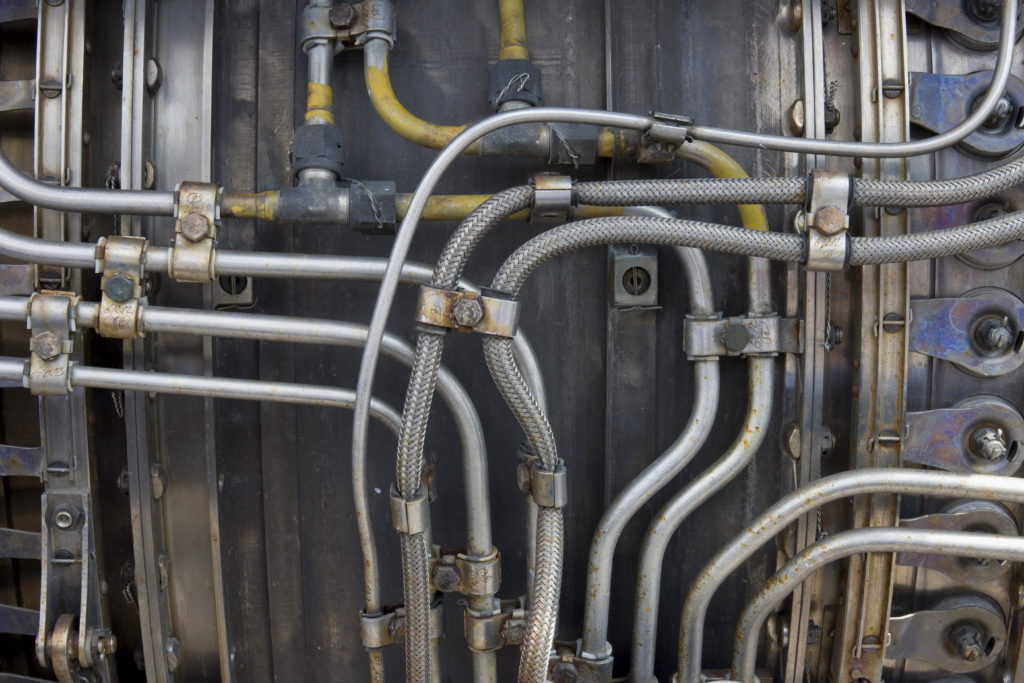

Cost-effective solutions for aeroderivative ground-based turbines

Conax exhaust gas sensors for LM6000 and LM2500/LM5000 Conax Technologies has a proven history of...