Furnaces

Solutions for the Furnace industry

View our solutions for the furnace industry

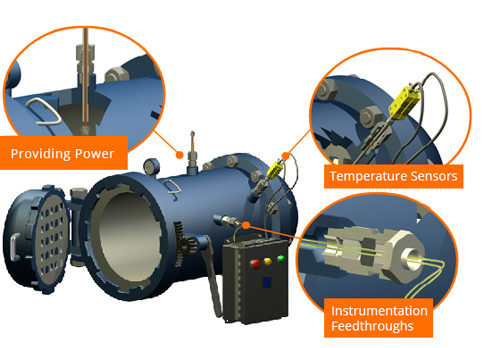

Conax designs and manufactures high-quality solutions for providing power, accurately monitoring temperatures, and providing reliable, secure feedthroughs for instrumentation. Click here to view our products.

Solutions for Providing Electrical Input

If you need to provide electrical input to a fan, motor, heater or other AC or DC powered device, Conax has two great solutions covering virtually any power feedthrough requirement. Our power series compression seal fittings are simple and reliable mechanical pressure and vacuum seal fittings to supply high voltage or current to your equipment and protect your environment.

Single Electrode Style Compression Seal Fittings—Our single electrode style compression seal fittings allow for up to 525 amps per single electrode at up to 8000 VDC. Products include:

- High Voltage Power Feedthrough (EGT)

- High Voltage/Pressure Power Feedthrough (HEGPK)

- High Temperature Power Feedthrough (EG)

Power Lead Style Compression Seal Feedthroughs—Our Power Lead (PL) compression seal feedthroughs provide multiple sealed, insulated wires for inserting power into a furnace.

Temperature Sensor Solutions

Conax Technologies is the industry leader in the design and fabrication of temperature measurement devices. Conax temperature and control sensors are used throughout the furnace industry in a variety of processes. Our products include:

Instrumentation Feedthrough Solutions

Conax Technologies’ sealed feedthroughs and compression seal fittings have proven to be the industry leaders in quality and performance. We’re the originators of soft sealant technology that, when combined with mechanical compression, results in a remarkably secure seal on wires, probes, and electrodes passing through a pressure or environmental boundary. The solutions listed below are commonly used in furnaces.

Feedthroughs with factory-installed lead wire are available in copper or thermocouple wire and include:

- General Purpose Instrument Lead (TG – 24T)

- High Temperature Instrument Lead Feedthrough (TGF)

- High Pressure Ruggedized Feedthrough (PL)

- High Density Wire Feedthrough (HD)

Feedthroughs without factory-installed lead wires include:

-

- Multiple probe or wire seal fitting

- Compression seal fittings for vibration sensors, humidity sensors, pressure sensors, control sensors, and more

- Single probes or sensors

- Split fittings for sealing on cables/wires with connectors or sensors larger than cable diameter (SPG & DSPG)